• Cement (Portland)

• Sand (if you are able to get sand from a quarry, do so, as it will save you a significant amount of money)

• Gravel (fine grade)

• Clay soil

• Clay (we used 5 litres regular abbots ceramic clay)

• Metal Mesh (reinforcing for concrete slab)

• Vermiculite (100L Bag from ‘Switched on Gardener’)

• Red Clay Bricks

• Fire Bricks (We found ours on Trade Me. They had been taken out of an old night store heater).

• Fire Clay Flue (or stainless steel flue. Do not use ceramic pipe as it will crack with the heat)

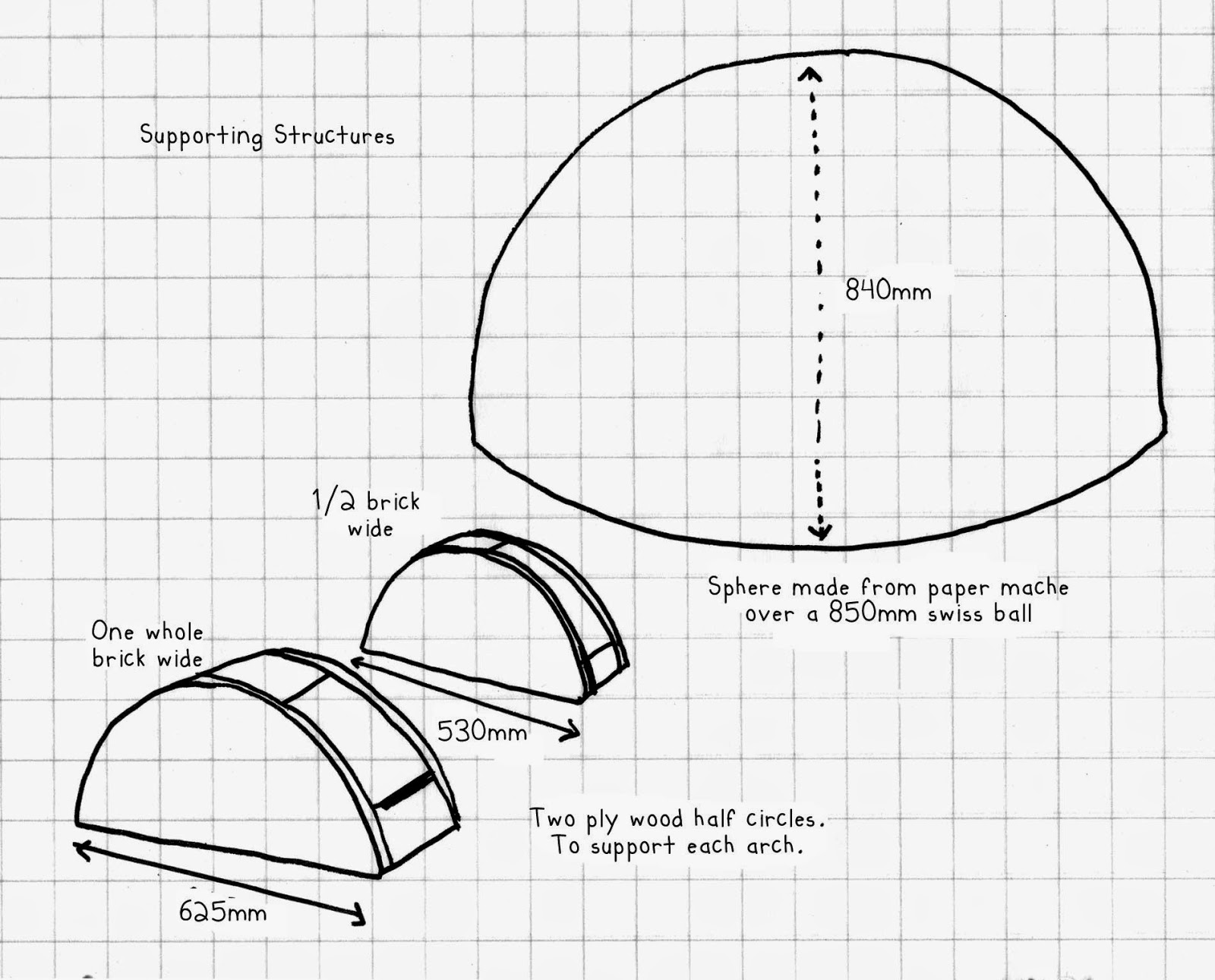

• Paper mache dome: made around a 85cm Swiss Ball (Sourced from Trade Me) using newspaper/wallpaper paste

• Mallet and Cold Chisel (to break bricks in half from any hardware store)

• Ply Wood (for two arches)

• Chicken Wire

• Trowel

• Black Oxide (to colour final plaster/cement layer)

• Waterproofing agent for cement (we used ‘multibond’ from Mitre 10/Bunnings)

optional: refractory mortar

NB: We were able to resource/recycle many elements of our Pizza Oven for free or at a very low cost such as clay soil (from our back yard), potters clay (given to us), red clay bricks (given to us), fire bricks (bought on TradeMe, having been recycled from a night store), flue (bought from a second-hand building materials yard), ply-wood (scrap wood pieces), chicken wire (scrap wire pieces).